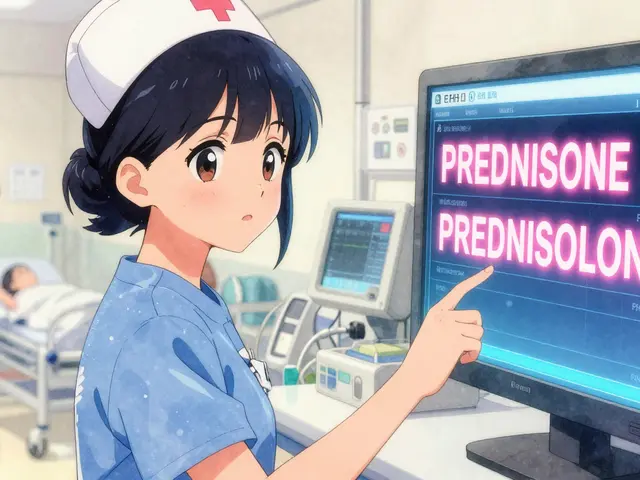

Active Ingredients: Are Generic Drugs Really the Same as Brand-Name Drugs?

Generic drugs contain the same active ingredients as brand-name drugs and are proven to work just as well. Learn how the FDA ensures equivalence, why generics cost far less, and when switching is safe-and when to be cautious.